Introduction to Molds

Overview of Composite Materials

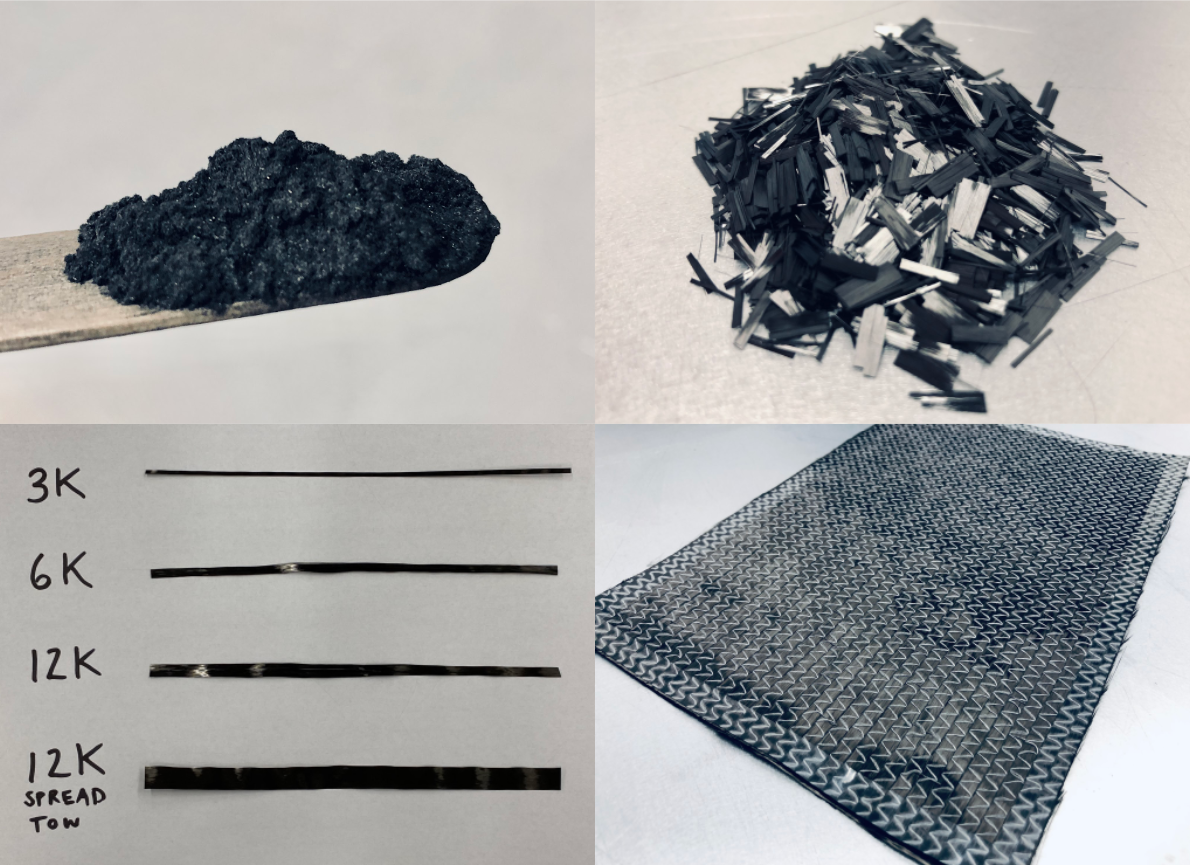

This course provides an overview of molds that can be used to manufacture parts made from composite materials. Composite materials are created by combining at least two different materials on a macroscopic scale to create a new material with properties that are a blend of the individual components. “Composites” is a broad term that encompasses a wide range of materials, but as used in this course, “composites” will specifically refer to fiber-reinforced polymer composites such as carbon fiber, glass fiber, or aramid fiber combined with a polymer matrix material such as epoxy resin. The fiber reinforcement can be in a milled, chopped, continuous, or woven fiber form.

The fiber reinforcement provides the majority of the strength and stiffness within the composite material, while the matrix material stabilizes the fibers allowing them to maintain a specific shape and support a wide range of loading conditions. Molds can be used to establish a specific shape for the fiber and resin as they are combined and cured. The process used to combine the fiber reinforcement and matrix material can range from a small scale manual process such as wet layup all the way up to a large scale production level with fully automated fiber placement and autoclave curing. For a more thorough understanding of composite materials, reference the DarkAero Aerospace Composites Course.

What is a Mold?

In the context of composite part manufacturing, a mold is a rigid or semi-rigid surface representing the desired shape of a part. A mold constrains the fiber-reinforcement and matrix material to a specific geometry until the matrix is cured to a sufficiently rigid state for the composite part to be removed from the mold and still maintain its intended shape.